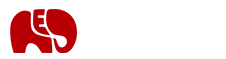

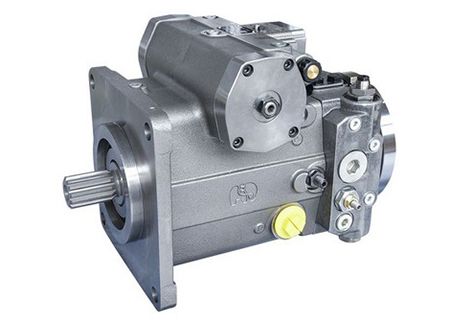

K4VSO(Replacement for A4VSO)Replacement hydraulic pump for A4VSO axial piston variable pump

- Robust high pressure pump for industrial applications

- Size 40ml/r-500ml/r

- Series 1, 2 and 3

- Nominal pressure 35MPa

- Peak pressure 42MPa

- Open circuit

- Variable displacement axial piston pump K11VSO with swashplate structure, designed for open circuit hydrostatic drives

- The flow is proportional to the drive speed and displacement, which can change steplessly by adjusting the swashplate angle

- Excellent suction characteristics

- Low noise level, long service life

- Drive shaft capable of absorbing axial and radial loads

- Modular design, good power/weight ratio

- Short control time

- Through drive for mounting additional pumps

- Swashplate angle indicator

- Optional mounting position

- Operation on HF fluids possible with reduced operating parameters

| Size | | | | | | | | | | | | ||

| Displacement | Vg max | cm3 | 40 | 71 | 80 | 125 | 18 | 200 | 250 | 300 | 355 | 370 | 500 |

| Rotating speed | no max | r/min | 2600 | 2200 | 2200 | 1800 | 1800 | 1700 | 1500 | 1500 | 1500 | 1500 | 1320 |

| Max. rotating speed | no max zul. | r/min | 3200 | 2700 | 2700 | 2200 | 2100 | 2000 | 1800 | 1700 | 1700 | 1700 | 1600 |

| Flow | nE=1500r/min | L/min | 60 | 107 | 121 | 186 | 270 | 283 | 375 | 450 | 532 | 555 | 750 |

| Power | nE=1500r/min | kW | 35 | 62 | 70 | 109 | 158 | 166 | 219 | 262 | 311 | 324 | 437 |

| Torque | ng max | Nm | 64 | 113 | 113 | 199 | 286 | 286 | 398 | 478 | 564 | 588 | 795 |

| Weight | kg | 39 | 53 | 53 | 88 | 102 | 102 | 184 | 184 | 207 | 207 | 320 | |

| Max. axial force | N | 600 | 800 | 800 | 1000 | 1400 | 1400 | 1800 | 2000 | 2000 | 2000 | 2000 | |

| Max. radial force | N | 1000 | 1200 | 1200 | 1600 | 2000 | 2000 | 2000 | 2200 | 2200 | 2200 | 2500 | |

- Efficient hydraulic operations require the careful selection of hydraulic fluids for your system according to the operating conditions. Most mineral-oil based hydraulic fluids are suitable for axial piston pump components. Water/oil content and viscosity-temperature relationship are central to a correct fluid selection. Other important parameters include oxidation and corrosion resistance, material compatibility, and separation characteristics in water and air.

- Correct filtering in lubricants and fluids is essential for axial piston units' long and satisfactory life. To ensure proper functioning, the maximum permissible contamination class are:

NAS1638 Class 9; SAE Code 6; ISO/DIS4406 Class 18/15;

For high fluid temperatures:

NAS1638 Class 8; SAE Code 5; ISO/DIS4406 Class 17/14 - To choose the right type of hydraulic fluid, it is essential to consider the operating temperature related to the ambient temperature. The operating temperature is the temperature of the circuit for closed circuits or the tank's temperature for open circuits.

- Please note that the case drain temperature is affected by pressure and speed and is always higher than the temperature of the circuit. It is required that the temperature of any circuit component shall not exceed 90℃.

Please consult our technical support for orders for usage in extreme working environments with operating temperatures lower or higher than the limits. - The inlet pressure of the pump should be greater than 0.08 MPa (absolute pressure), and the discharge pressure (the maximum allowable pressure in the casing) should be 0.4 MPa (absolute pressure). Pressure in the casing must be greater than or equal to the external force acting on the shaft seal.

- Mounting position: By default, axial piston variable pump, axial piston variable motor and case upper edge should be mounted below the minimum oil level of the tank. Please mention if the pump needs to be mounted above the oil level when ordering.

- Installation of the coupler: Install the coupler with flat-key shaft using an oil bath. Put the coupler matched with the pump shaft into the oil bath with a temperature lower than 90 ℃, and let it heat for 40 minutes, then assemble the shaft and coupler, cool it down quickly by water. and then fasten the screws on the flat-key shaft. DO NOT strike shaft when assembling coupler which can cause damage to the bearing. Avoid hoisting or carrying the hydraulic pump from the main shaft.

If you are still struggling to find the right product, or have request for quotation, or any concerns about our products, our experts will be happy to assist you.

Guangdong KEDA Hydraulic Technology Co., Ltd. is an industry leader in producing high-pressure piston pumps and high-speed motors, leveraging our core technology to provide superior technical solutions for customers worldwide. Our products including hydraulic pumps, hydraulic motors and hydraulic spare parts are used across a wide range of industries, including metallurgy, forging, TBM, building materials, pile drivers, mobile machinery, and marine engineering. We have domestic and international sales and service bases to ensure fast and satisfactory services for all our customers. As part of KEDA Industrial Group Co., Ltd. (stock code 600499), we strive to offer innovative solutions that exceed expectations every time.