Hydraulic Motors

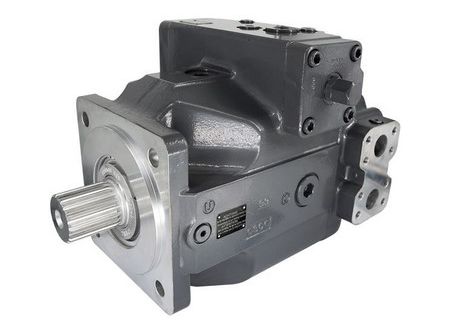

Axial piston variable displacement motors are variable motors of the bent-axis design with axial piston rotary group for hydrostatic drive in open and closed circuits. In axial piston units with a bent axis design, the pistons, converting hydraulic pressure and angular displacement into torque, are arranged diagonally to the shaft and located directly above it. Specific torque and displacement can be achieved by adjusting the swashplate. In an open circuit, the hydraulic fluid flows from the reservoir to the hydraulic pump, where it is fed to the hydraulic motor through the directional valve. The output direction of rotation of the hydraulic motor can be changed, for example, by a directional valve. In a closed circuit, hydraulic fluid flows from the hydraulic motor directly back to the axial piston pump. Reversing the flow of hydraulic fluid in the pump changes the rotational output of the hydraulic motor.

-

K6VM(Replacement for A6VM)

- All-purpose high pressure motor

- Series 63, 65, 71

- Nominal sizes: 80, 107, 160, 170, 200, 215, 500

- Nominal pressure 400 bar

- Maximum pressure 450 bar

Axial Piston Variable Motor K6VM(Replacement for A6VM)

-

K6VE(Replacement for A6VE)

- High pressure motors suitable for integration into mechanical gearboxes

- Series 63, 65, 71

- Nominal size 28, 55, 80, 107, 160, 170, 200, 250

- Nominal pressure 400 bar

- Maximum pressure 450 bar

Axial Piston Variable Motor K6VE(Replacement for A6VE)

-

K4VSM

- For open or closed circuits

- Sizes 40-500

- Maximum nominal pressure 350 bar

- Maximum peak pressure 420 bar

Axial Piston Variable Motor, K4VSM

Fixed displacement axial piston motors are plug-in fixed motors with an bent axis design, equipped with axial conical piston rotary bodies for hydrostatic drives in open and closed circuits. In axial piston units with a bent-axis design, the pistons, converting hydraulic pressure into torque, are arranged diagonally to the shaft and located directly above it. In an open circuit, the hydraulic fluid flows from the reservoir to the hydraulic pump, where it is fed to the hydraulic motor through the directional valve. In a closed circuit, hydraulic fluid flows from the hydraulic motor directly back to the axial piston pump. Reversing the flow of hydraulic fluid in the pump changes the rotational output of the hydraulic motor.

-

K2FE(Replacement for A2FE)

- High pressure motors suitable for integration into mechanical gearboxes

- Size 56 … 180

- Nominal pressure 400 bar

- Maximum pressure 450 bar

- Open or closed circuits

Axial Piston Fixed Motor K2FE(Replacement for A2FE)

-

K2FM(Replacement for A2FM)

- All-purpose high pressure motor

- Size 56 … 180

- Nominal pressure 400 bar

- Maximum pressure 450 bar

- Open or closed circuits

Axial Piston Fixed Motor K2FM(Replacement for A2FM)

-

K4FM(Replacement for A4FM)

- High pressure motors suitable for confined spaces

- Size 71 to 500

- Nominal pressure 350 bar

- Maximum pressure 400 bar

- Open or closed circuits

Axial Piston Fixed Motor K4FM(Replacement for A4FM)

Guangdong KEDA Hydraulic Technology Co., Ltd. is an industry leader in producing high-pressure piston pumps and high-speed motors, leveraging our core technology to provide superior technical solutions for customers worldwide. Our products including hydraulic pumps, hydraulic motors and hydraulic spare parts are used across a wide range of industries, including metallurgy, forging, TBM, building materials, pile drivers, mobile machinery, and marine engineering. We have domestic and international sales and service bases to ensure fast and satisfactory services for all our customers. As part of KEDA Industrial Group Co., Ltd. (stock code 600499), we strive to offer innovative solutions that exceed expectations every time.